The Application of

Ultrasound for Plating Industry

HIGH POWER

RELIABILITY, DURABILITY

Experts in the application

of Ultrasound for Electroplating

Exclusive features

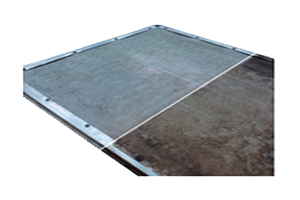

Ultrasounds are widely used in Plating Industry, in the coating preparation tanks and in the final cleaning tanks, in demineralized water through the application to the tanks of one or more Immersible Transducers powered by one or more SCUDO Generators.

Panatronix manufactures manual and automatic ultrasonic cleaning plants for in-depth cleaning of surfaces in industrial processes.

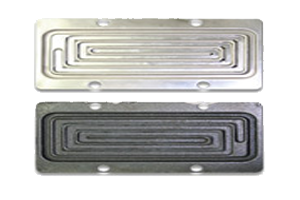

SCUDO ultrasonic generator (patented)

All electronic parts inside the Generator are isolated and protected thanks to the incorporated “SCUDO” heat exchanger.

An indispensable ally in particularly harsh environments such as electroplating.

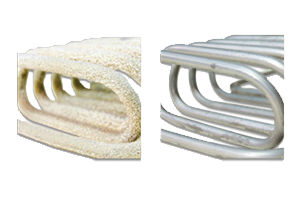

Ultrasonic Immersible Transducers

The exclusive material of the Immersible Transducers has unique characteristics, able to last over time, withstand medium / high powers and suitable for continuous use (average use: about 10 years for 8 working hours a day). It is a special anti-erosion and anti-corrosion material, much higher than AISI 316L stainless steel.

Ultrasound for ElectroplatingPreparation and surface finishes

Removing cleaning pasteoils and lapping

The combined action of cavitation with an appropriate cleaner removes within seconds any type of oils and/or cleaning paste from pieces of brass, zinc alloy, aluminum, iron, steel etc. Depending on the case using the frequencies and powers most suitable. Process used directly in Plating Industry (zinc, chrome etc.). The advantages of Ultrasound for Electroplating.

Welding

cleaning

Halos, oxides, burned oils are removed in a few minutes from welded pieces in copper alloys or ferrous material. The strong mechanical action of cavitation of ultrasounds, combined with appropriate detergent enables the removal of very corrosive acids (hydrochloric, nitric, sulfuric etc.) and its toxic and harmful emissions. Process can also be used in Plating Industry (zinc, chrome etc.). The advantages of Ultrasound for Electroplating.

Pickling of ferrous materials

Elimination of calamine and oxides from thermal deburring. Quick removal of deposits caming from melting processes, die casting, hot forging and heat treatments on particular copper or its alloys, cast iron, AVP etc .. Process can also be used in Plating Industry. The advantages of Ultrasound for Electroplating.

Deoxidationof non-ferrous materials

Removal of oxides of copper, alloys and halos of soudobrasage. The operation is done in a few seconds and the pieces are uniform and deoxidized. Process can also be used in Plating Industry. The advantages of Ultrasound for Electroplating.

Final washing in demineralised water andpreparation for PVD coating

The action of ultrasounds cavitation is particularly suitable for rinsing to eliminate detergent residues in Electroplating. It is also used in the final washings in demineralised water to eliminate the entrainment of the coating material (chrome, gold, etc.). Ultrasound plays a fundamental role in the preparation for PVD coating where extremely thorough cleaning is required.

Ultrasonic cleaning tanks - cleaning and maintenance

The application of ultrasound for the removal of contamination

The applications of ultrasound in the world of work are many, in the most disparate sectors. There are some areas where the removal of impurities from surfaces is particularly difficult.

The advantage of Panatronix ultrasonic cleaning tanks is to be able to remove dirt from surfaces quickly and accurately, reaching all those internal areas, cavities, which are not easily accessible by traditional cleaning systems.

Furthermore, if we think about the removal of contamination, such as:

greasy and oily substances, limestone and oxides, glues, hot melts and carbon residues

we know well that it often takes a considerable waste of time, labor and detergents to have an almost discreet cleaning of the surfaces.

Panatronix ultrasonic cleaning tanks are a valid solution to save time, labor and detergents and allow you to obtain an optimal and deep cleaning.

Built to last over time, with special materials, they use the same criteria of efficiency, duration, reliability and safety used in the industrial sector.

Simple in their use, special and modular for the most demanding requests.

Grids and filters

cleaning

Boilerscleaning

Pre-paintingcleaning

Traycleaning

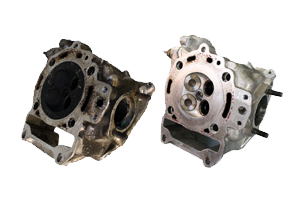

Cleaning of molds for

metals and plastics

Cleaningfrom carbon residues

enginecleaning