The Application of

Immersible Transducers

Reliability, Duration

Constant performance over time

Panatronix presents the NEW production of

ULTRASONIC IMMERSIBLE TRANSDUCERS

Connected to the respective Generators, the Panatronix’s Ultrasonic Immersible Transducers, vibrating at ultrasonic frequency, give rise to the phenomenon called “cavitation” which, combined with an appropriate chemical action of the aqueous detergent, removes impurities in every point of the objects immersed in the ultrasonic washing tank.

TRANSFORM

YOUR TANK

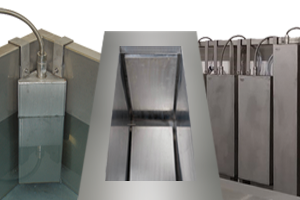

By applying the Ultrasonic Immersible Transducers Panatronix, any washing or rinsing tank is transformed into an ultrasonic tank.

IN AN ULTRASONIC

WASHING TANK

The number, position and power of Immersible Transducers depend on the volume of the liquid, the mass, the shape and the type of the parts to be washed.

APPLYING ONE OR MORE

IMMERSIBLE TRANSDUCERS

Over 30 series models. Upon request, special dimensions Ultrasonic Immersible Transducers are produced.

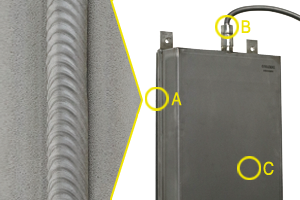

SPECIAL MATERIALAND TIG WELDING

The Panatronix’s Ultrasonic Immersible Transducers are built in special anti-erosion and anti-corrosion material (C), on request in titanium alloy for highly corrosive liquids. Equipped with Flexsonic (B) and highly resistant thanks to robotic Tig welding (A).

FLEXIBLEAPPLICATIONS

The Panatronix’s Immersible Transducers can be applied: Corner (indicated in the absence of lateral space); Wall (with Flexsonic tube or single hole flange); on the Bottom (with Flexsonic tube or single hole flange.

FLEXSONIC

TUBE

The Panatronix’s Immersible Transducers are equipped with Flexsonic (patented), a flexible tube, resistant to ultrasonic cavitation. Consisting of a double coaxial PTFE tube with independent seals.

Reliability Duration Constant performance over time

Connect to the respective Generators the Immersible Transducers vibrate at ultrasonic frequency and give rise to the "Cavitation" phenomenon

Characteristics of the

Ultrasonic Immersible Transducers

JUNCTION

GI.MET

The vibrating elements contained in the transducer are piezoelectric (PZT) with high intensity and efficiency, and transmit the vibration to the surface of the transducer through a special and exclusive plant of metallurgical junction.

LIFE TIME

WARRANTY

Unlike traditional junctions, subjected to phenomena of progressive aging and detachment, the GI.MET junction is guaranteed for the entire duration of the vibrant surface.

PERFORMANCE OVER 98%

The metallurgical joint allows a transmission of energy complete and constant in time.

AUTOMATED TIG WELDING

Compared to normal manual welding, ensure maximum durability.

SYSTEM OF WATERTIGHT SEAL WET-LESS

Guarantees against atmospheric humidity.

MATERIALS AND COATINGS

The Immersible transducers are made of an exclusive alloy with anti-erosion and anti-corrosion.

Custom applications of Ultrasonic Transducers