The Science of

Ultrasound at Work

HIGH POWER

RELIABILITY, DURABILITY

ULTRASONIC CLEANING NEW PRODUCTION

Ultrasonic Generator and Transducers manufacturers

For over 30 years we have been producing ultrasounds for industrial cleaning and developing innovative solutions for cleaning surfaces with results superior to traditional ones.

Our ultrasound equipment basically consists of a current Generator that powers one or more Immersible Transducers.

We build Immersible Transducers able to adapt to any type of industrial reality, thanks to their easy application, shape and size.

Based on the volume of the liquid, the mass, the shape and the type of the pieces to be washed, we determine the number, the position and the power of the Generators and Immersible Transducers.

Manufacturers of tanks and plants

In addition to the production of Generators and Transducers, we produce a series of special ultrasonic cleaning machines that satisfy the most demanding customers.

For those who are looking for a “standard” product but at the same time respecting the balance between quality, price and durability, we have designed a line of ultrasonic cleaning tanks with unique characteristics, called “UNIKA“.

For those who require a more advanced high-performance cleaning plants (modular, with descender, with oil separator, rinsing, drying, manual or automatic translation of the baskets, etc.), we build industrial ultrasonic cleaning plants.

The science of ultrasound

Ultrasounds are acoustic waves with a frequency higher than the maximum audibility limit, measured in Hertz (abbreviated Hz). The human ear perceives sounds between 20 Hz and 20,000 Hz. Above 20,000 Hz we speak of ultrasonic waves.

The Ultrasonic frequency is one of the factors that determine the effectiveness of cleaning. Knowing how to choose the most suitable frequencies is certainly an advantage that brings more immediate results.

Another factor that plays a fundamental role in the ultrasonic cleaning process is the physical phenomenon called “cavitation“. This phenomenon generates a great deal of energy and has a powerful mechanical action, which combined with an appropriate detergent, easily removes contamination from any surface, pre and post surface treatments.

Therefore the use of a valid ultrasonic equipment proves to be an excellent solution for industrial cleaning.

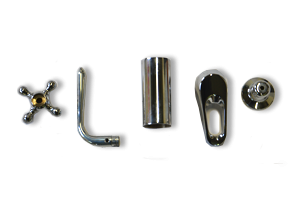

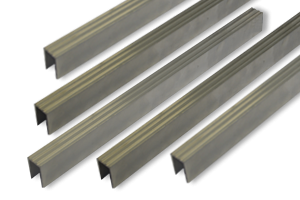

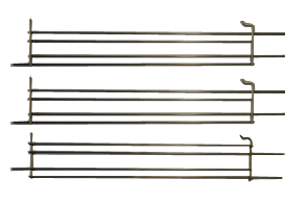

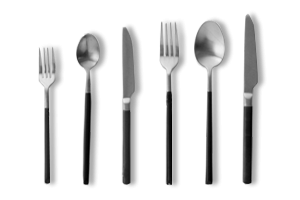

Ultrasonic cleaning for Industryand its applications

Galvanic chrome plating

Galvanic electrolytic zinc plating

Galvanic anodic oxidation

Chemical nickel plating

PicklingElectro polishing

Silver plating and gilding

Cleaning pastes and oils

PVD cleaning

Cleaning of chains and accessories

Deoxidation after heat treatment

Deoxidation after welding

Deoxidation after thermal deburring

Wire drawing cleaning

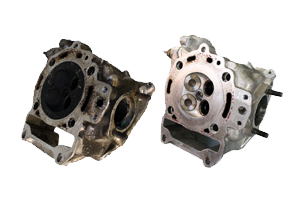

Cleaning of molds for metals and plastics

Cleaning from carbon residues

Engine cleaning

Descaling cleaning

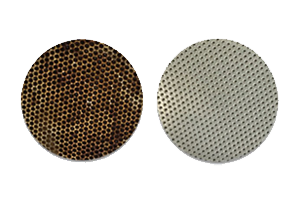

Filter cleaning

The choice of ultrasound

Some important factors to keep in mind when choosing ultrasound:

It is important to rely on a company that focuses on innovation, which patents new solutions and always offers cutting-edge products. Panatronix has designed ad hoc solutions for some of its customers and patented inventions such as the “Scudo” heat exchanger and the Flexsonic tube. In addition, he has collaborated with some prestigious universities making his experience available.

It is important to rely on a company that always aims at the efficiency and quality of its products and services. Panatronix employs special materials, offers long-lasting ultrasound, high power and resistance.

Panatronix makes the knowledge acquired in more than 30 years available to the customer. Furthermore, it has a consolidated experience in solving problems related to galvanic preparation and intermediate and final washing.

Panatronix is alongside the customer in all its phases: from identifying the problem to its solution. It is not just be a supplier company but rather a partner you can rely on. An example of this is the degreasing, washing, pickling tests on customers’ samples carried out free of charge in your own laboratory.

When choosing ultrasound it is important to pay attention to:

Depending on the surfaces to be treated and the type of impurities, the most appropriate ultrasound frequencies are chosen. In the case of more tenacious contaminants, lower frequencies will be used, on the contrary, to remove the lighter ones or micro particles, higher frequencies will be needed. In cleaning, the frequencies vary from 20 to 200 KHz.

Every equipment is always and in any case subject to wear phenomena that reduce its life. It is equally true that good design, construction and careful maintenance increase its durability.

Panatronix pays close attention to the durability and resistance of its ultrasound. In this regard, it has solved numerous problems, common to industrial environments, by making changes to its ultrasound devices making them far superior to traditional ones.

Longer life for the Generator

Problem: the generator is an air-cooled electronic device, whose filters are not sufficient to protect against dust and vapors present in particularly harsh industrial environments such as galvanic.

Solution: Panatronix has definitively solved the problem by isolating and protecting all the electronic parts by means of the heat exchanger built-in “SCUDO” (patented).

Longer life for the Transducer

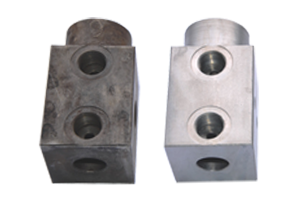

Problem: continuous vibrations, high erosion due to cavitation, poor resistance of material and the continued use of high power progressively reduce the performance of the transducer surface, until it becomes unusable.

Solution: Panatronix solved the problem.

Since 2000 it has been using a special and exclusive anti-erosion and anti-corrosion material with characteristics far superior to AISI 316 stainless steel, such as to allow an average use of about 10 years for 8 hours of work per day in high power (ultrasound in galvanic).

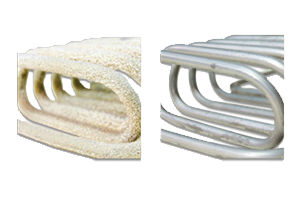

Furthermore, to ensure maximum tightness and constant performance over time, Panatronix applies precision Tig (robotic) welding on its Immersible Transducers and uses the innovative Flex Sonic tube (patented) able to resist ultrasonic cavitation.

Power is another important element to consider. For each type of application the necessary ultrasound power and its correct distribution in the washing tank must be calculated. there are those who do not pay attention and therefore make calculation and evaluation errors. For this reason Panatronix is happy to give a short explanation to facilitate understanding. Let’s clarify some concepts right away:

Real power is measured in Watts and should not be confused with apparent power which is measured in VA.

The peak power (Peak) is only an instantaneous value and has nothing to do with the real power or maximum output power.

Peak power is usually indicated with double value of the real one and sometimes quadruple, play on the misunderstanding that peak power is the maximum power that can be delivered. Taking into account the volume of the liquid we can say that the applied ultrasonic power is often expressed in Watts/liter. The required power is calculated based on the physical-chemical parameters of the liquid and pieces. Panatronix is specialized in high power and performance with generators from 1.000-2.000-3.000-4.500-6.000-8.000-10.000 Watt each.

For any in-depth analysis or test of ultrasound washing efficiency, contact Panatronix.