Textiles and Ultrasounds

together for sustainability

water saving,

greater colour penetration

lower consumption of chemical products

Panatronix has developed a revolutionary technological solutionaimed at the dyeing and finishing lines for yarns and textiles

Ultrasounds as a solution for a more sustainable future

For years, the textile industry has faced three major challenges: saving water, reducing the consumption of chemical products and optimize the time of process.

Although several studies have been carried out to reduce the environmental impact, no one had ever thought of ultrasounds as a solution for a more sustainable future.

Today Panatronix, leader in the production of ultrasounds and expert in industrial washing, has developed a revolutionary technological solution, aimed at the dyeing and finishing lines for yarns and textiles.

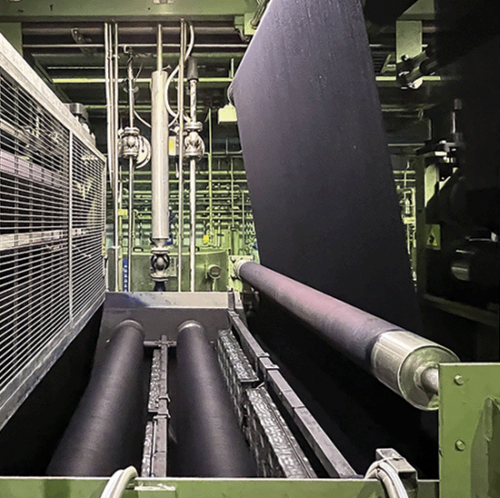

The Panatronix ultrasounds have been installed on 4 Master dye lines at Candiani Denim, international manufacturer of denim fabric, sharing the same principles of uniqueness, quality, sustainability and innovation.

7

incredible advantages obtained by the application of ultrasounds in the textile industry

1

REDUCTION OF WASH WATER CONSUMPTION BY UP TO 60%, DEPENDING ON THE TYPE OF INDUSTRIAL PLANTS EVEN AT LOWER TEMPERATURES, AND CONSEQUENT SAVINGS IN PURIFICATION

2

CHEMICALS SAVING DUE TO THE DEGASIFICATION GENERATED BY THE MECHANICAL ACTION OF ULTRASOUNDS UP TO 40% LESS HYDROSULPHITE AND LESS SODA, DEPENDING ON THE TYPE OF INDUSTRIAL PLANTS

3

BETTER COLOR PENETRATION

4

INCREASED FIBER CLEANING AND REMOVAL OF IMPURITIES

5

REDUCTION OF PROCESS TIMES

6

REDUCTION IN THE NUMBER OF DYE BOX (tank)

7

DECREASE IN BATH VOLUMES IN STORAGE

EASE OF APPLICATION AND DURABILITY

The ultrasonic system consists of some panels called “Immersible Transducers” and a power generator.

The transducers are easy to apply in any pre-existing washing box (tank) or in slasher or rope dyeing plants, without any structural modification of the boxes.

The size and position are always appropriate to the type of box (tank) and available space.

The special material, anti-erosion and anti-corrosion, with which the transducers are built, guarantees a high resistance and long durability.

The transducers and their generators are designed to work at special frequencies identified with experience gained in the sector.

In addition, Panatronix, with the contribution of Archroma, a global leader in chemical products for the textile sector, has carried out multiple laboratory tests that have confirmed the effectiveness of ultrasound on yarns, fabrics and dyes.

JOIN IN THE CHANGE, BUILD THE WORLD OF TOMORROW, TODAY!

Contact Panatronix and learn more about the benefits that ultrasound can bring to your dyeing and finishing line.

Textiles and Ultrasounds